The World of Applications

Diamonds possess a remarkable combination of attributes that render them invaluable in various industrial applications. Not only are they the hardest naturally occurring substance, but they also exhibit exceptional resistance to wear and high thermal conductivity. With a high index of refraction, pronounced dispersion, and unparalleled luster, diamonds are highly sought after in industries for their multifaceted utility. These exceptional properties make diamonds ideal for use as abrasives, heat sinks, and even in the production of diamond speaker domes and wear-resistant components.

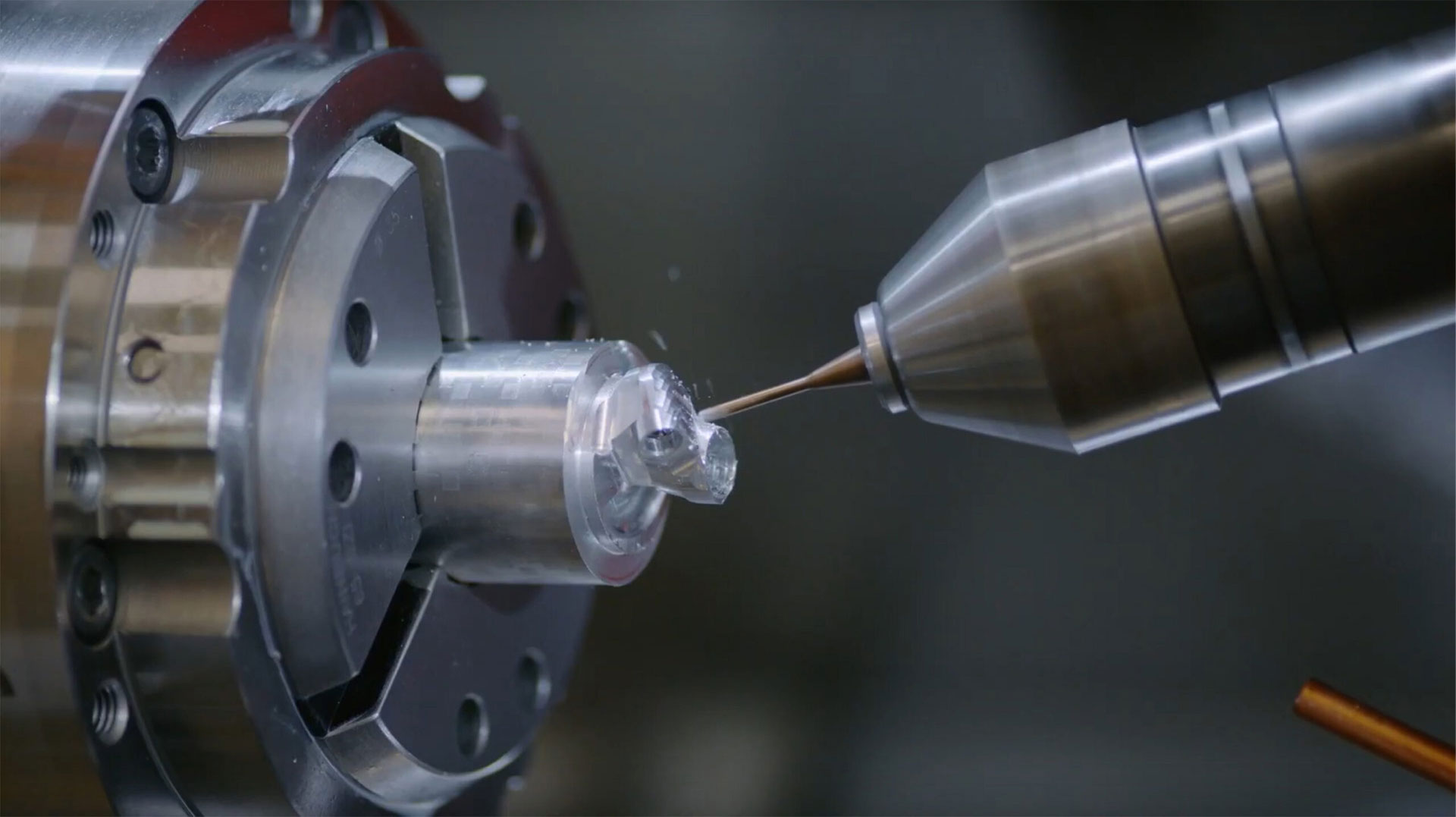

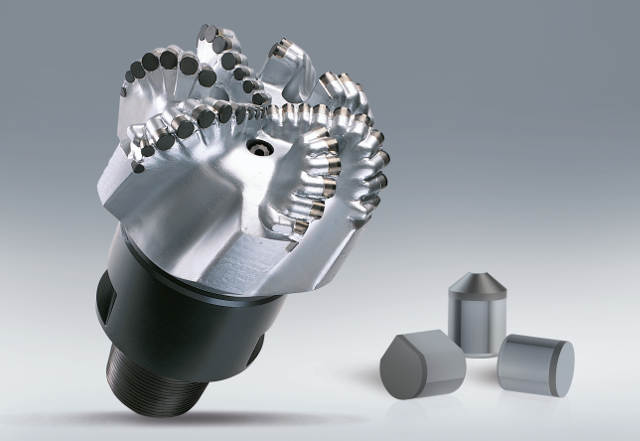

The exceptional hardness of diamonds, with a Mohs hardness rating of 10, positions them as unparalleled cutting tools and grinding agents in various industrial processes. Their unmatched durability and cutting prowess make them a preferred choice for precision cutting and grinding tasks, especially when dealing with hard materials. Synthetic diamonds, cultivated in laboratory settings, have gained widespread recognition for their role in enhancing grinding, drilling, and polishing operations. Moreover, small diamonds of gemstone quality, too petite for conventional cutting, find purpose and utility across numerous industrial sectors.

Diamonds possess exceptional thermal conductivity, allowing them to effectively absorb and dissipate excess heat. This quality makes diamonds invaluable in the realm of microelectronics, where they serve as efficient heat sinks. By utilizing diamonds in this manner, sensitive electronic components are shielded from the harmful effects of excessive heat, ensuring their optimal performance and longevity.

Furthermore, a thin diamond coating is employed to create wear-resistant components capable of withstanding high levels of wear and tear, as well as abrasion. This protective diamond layer enhances the durability and longevity of various parts and surfaces, making it an indispensable solution in industries where resilience and longevity are paramount.